The designs are finished, and the massive—even 'romantic'—Gigafactory is spinning into motion.

It's official: The pencils are down.

Tesla Chief Executive Officer Elon Musk told a roomful of reporters on Tuesday that the final designs for Tesla's $35,000 electric Model 3 were locked up two weeks ago, and the company is moving forward on schedule to start producing them next summer. That was just the beginning.

Musk, 45, spoke in a room lined with windows looking out onto the grounds of what's rapidly becoming the biggest building in the world: Tesla's battery Gigafactory. When complete, the three-story building will be about the size of New York's Central Park. To put it another way, 107 football fields could fit inside its footprint.

The diamond-shaped factory in the scrubland outside Reno, Nevada, is surrounded by thousands of wild horses that drink from construction ponds at the Gigafactory. Musk says the project inspires in him a sense of Wild West romance—which is perhaps why he opened himself up to a wide-ranging interview that covered everything from proprietary battery design to the book he's reading in his spare time.

Here are eight big takeaways from a tour of the Gigafactory and a Q&A session with Musk, Chief Technology Officer J.B. Straubel, and Panasonic executive Yoshihiko Yamada.

1. Battery prices are falling to $100 per kilowatt hour

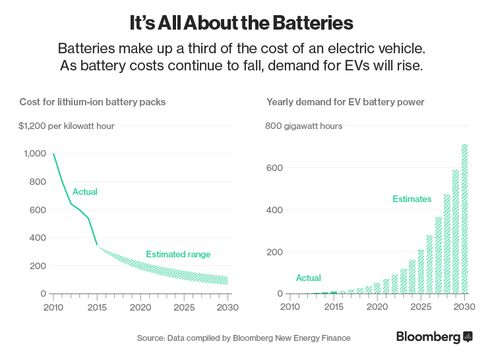

This fact may sound esoteric, but it's incredibly important. Batteries make up a third of the price of an electric car and are the only reason these vehicles have been more expensive than their gasoline counterparts. Musk said he's confident the company will reach a price of $100/kWh by 2020 (down from an average price of $1,200 in 2010). If he's right, the economics of electric cars will flip, as will the case for battery-backed solar power.

Here's Bloomberg New Energy Finance estimates from where the industry was headed as of February. Given Musk's optimism, it might need some revisiting.

2. Battery costs are falling for three reasons

Cheaper materials, a shorter supply chain, and factory automation. The first is straightforward: Buying at Gigafactory scale lowers the procurement costs of raw materials such as lithium.

Supply chain costs are where some of the real breakthroughs are coming. Making a battery pack typically requires components from a dozen manufacturers. Each of those products must be built, packaged, shipped around the world, unpackaged, assembled together into a pack, repackaged, and shipped again.

That's not how things will work at the Gigafactory. Tesla plans to build a train line connecting the Gigafactory to its auto factory 240 miles away in Fremont, Calif. The Gigafactory will produce every aspect of the battery packs. Raw materials will enter the factory at one end, and finished packs will exit from the other end—on a train straight to Fremont.

A construction worker prepares the second story floor of "Section D" for cement. Some assembly for the Model 3 drive train will take place here.

Photographer: Troy Harvey/Bloomberg

Automation is the final cost-cutting step. Musk says that although the factory will probably employ around 10,000 people by around 2020, most major manufacturing processes are being automated. Some of his most creative engineers were assigned the task of building what will be a more efficient factory. "They can make five times as much headway per hour than if they work on the product itself," Musk said.

Tesla has even become its own construction company and is its own licensed general contractor, having hired top architects of football stadiums, the new Apple Inc. headquarters, and the Pentagon for its Gigafactory crew.

3. The Gigafactory has already cut the fossil-fuel lines for Tesla

Tesla cut and capped the natural gas line leading to the Gigafactory, so there's no going back to on-site fossil fuels. There's also no diesel generator for backup power. That means Tesla must rely on electricity for manufacturing processes that require heat, an unusual step for a major plant of any type.

By the time the facility is fully up and running, the Gigafactory is meant to be net zero for energy, powered mostly by onsite solar backed with batteries.

The view inside the Gigafactory.

Photographer: Troy Harvey/Bloomberg

4. Tesla wants to be a power plant

Ever heard of ride sharing? How about battery sharing? Last month, I wrote about how, by pursuing cousin company SolarCity Corp., Tesla may have designs on becoming its own electricity virtual power plant, aggregating bits of power from thousands of batteries and rooftop solar systems and selling that energy back to the grid. It's a hugely lucrative market, if Tesla can crack it, and on Tuesday Musk confirmed that he intends to.

"I think we'll get into grid services," he said.

5. Musk plans to spend and make a lot more money

Last week Musk released a sort of 10-year mission statement for Tesla, which he dubbed "The Master Plan, Part Deux." On Tuesday, he said the plan will cost tens of billions of dollars to implement.

However, he immediately clarified that the money would be spent over many years and that, in the meantime, Model 3 sales will more than make up for it. Musk said the Model 3 may bring in revenue of $20 billion a year (which works out to 500,000 cars at $40,000 a piece), with a 25 percent profit margin. He conceded that a "modest" capital raise might yet be necessary.

Musk describes the new battery cell size alongside Chief Technology Officer J.B. Straubel and Panasonic executive Yoshihiko Yamada.

Photographer: Troy Harvey/Bloomberg

6. More Gigafactories are coming

The Gigafactory schedule is being accelerated so Tesla can produce 500,000 cars in 2018, Tesla's Straubel said. Tesla's goal for 35 gWh of annual cell production by 2020 is now expected to come in two years ahead of schedule. The fully operational Gigafactory may be capable of three times the output originally forecast.

Musk says future Gigafactories will be necessary, combining all stages of production from battery cell production to finished cars. Expect plants in Europe, China, and possibly India, he said.

Only 14 percent of the Gigafactory is complete. Virtually everything shown here will be subsumed.

Photographer: Troy Harvey/Bloomberg

7. Tesla remains on Autopilot

Musk said he was “frustrated” by the media coverage from a fatal crash in Florida that happened while a driver was using Tesla's driver-assisting software. He insisted that the Autopilot technology has made the company’s cars safer.

Earlier on Tuesday, Mobileye NV, the maker of chips and software for driverless cars, said its cooperation with Tesla wouldn’t extend beyond its EyeQ3 product. Parting ways with Mobileye was “inevitable” and not surprising, Musk said. "They’ll go their path, and we’ll go ours."

8. Musk still takes time to read

Currently he's making his way through a book called, Twelve Against the Gods by William Bolitho, published in 1929. Bolitho, a South African journalist, wrote about 12 famous "adventurers"—from Alexander the Great to President Woodrow Wilson—who fought against the conventions of their times, for better or worse. It's out of print, but copies are readily available.

This wall is only temporary. It's there so construction can continue on the outside while batteries are made on the inside.

Photographer: Tom Randall/Bloomberg

No comments:

Post a Comment